|

|

|

Drinking

water tank

near Heilbronn rehabilitated

At the rehabilitation of a two-chamber

elevated tank, in Untergruppenbach near Heilbronn, the administration

unit 'Schozach-Wasserversorgungsgruppe' backed a high-quality thick

coating with only one material. The first chamber is once again

in operation and the remaining works shall be finished in July 2012.

The main elevated tank of the administration unit 'Schozach-Wasserversorgungsgruppe',

is situated in Untergruppenbach near Stettenfels Castle and has

a total volume of 2,000 m3. From here, the districts Untergruppenbach

and Obergruppenbach, Unterrheinriet and Oberrheinriet, Wüstenhausen,

Auenstein, Helfenberg and Abstetter Hof as well as the whole municipality

Abstatt is furnished with drinking water. In addition to its two

round chambers having a diameter of 18 m each and a height of four

meters each, the elevated tank has a mixing chamber in which the

water coming from Lake Constance and own water are brought together.

The right main chamber dates from 1972, the left chamber was already

built in 1959.

Round shows softened thin coating

In 2010, all supply plants of the administration

unit were examined by the engineering office Raith Plack von Scholley

on its requirement of repair. On the basis of this visual inspection

and an expert opinion on the concrete, the fundamental repair of

the elevated tank was determined during the meeting of the Association

under the chairmanship of the mayor of Untergruppenbach, Joachim

Weller.

Originally, the tank walls were equipped with a mineral thin coating,

which proved to be eroded and soft. In addition, corroded reinforcing

steel came to light. Besides, the concrete cover was no longer up

to the required standard and will be raised on all sides by three

centimetres in the course of the rehabilitation. The existing plant

and the process equipment will be rehabilitated as well.

General rehabilitation

with mineral mortar

To get permanent surfaces in the drinking water tank cement-bound

mortar is normally used. The quality of an internal coating depends

decisively on the material and its meticulous processing. It is

important to get an undamaged surface without penetrating pores.

In addition, the film thickness should be uniform and show a surface

which is as smooth and level as possible, so that soiling can deposit

hardly on the surface and cleaning is easier.

Universally applicable material

With the top 300, an especially high-yielding

shotcrete mortar came onto the market in 2009. It meets both the

hygienic requirements in accordance with the DVGW worksheets W 270

and W 347 and the technical requirements on building materials determined

in worksheet W 300/1. A handy peculiarity of the material is that

the mortar can be used universally on tank walls, tank ceilings

and tank bottoms. Even as a final coarse spray coating it leads

to an optically and functionally convincing surface. That simplifies

the material planning and prevents confusion on the construction

site. Ralph Weber, responsible for the field drinking water tanks

at epasit, amends: "The low modulus of elasticity and the good

setting of the material guarantee the quick return to service of

the water tank".

Complex rehabilitation and

emergency service

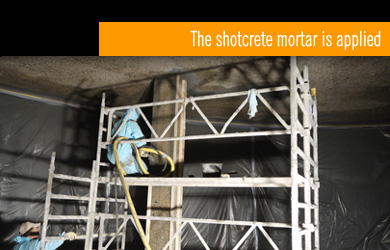

In Untergruppenbach, the new wet sprayed coating

applied as a thick coating has been planned as follows: ceiling

30 mm coarse spray, walls 30 mm smoothed, bottom 30 mm smoothed.

After having removed the defective thin coating, the corroded reinforcing

steel has firstly being smoothed. Then, the masons from the company

Bauschutz from Asperg applied the mineral thick coating with a film

thickness of about twice 15 mm. At the moment, the second chamber

is rehabilitated analogously. All in all, around 100 tons of mortar

have been used for the walls, ceilings, and bottoms of the three

chambers. The rehabilitation of the first chamber, which took place

already at the beginning of 2012, resulted to be particularly complex,

because during the works the whole water supply had to be carried

out via the left chamber and provisional arrangements for the pipe

cellar had to be set up. The existing pipe cellar will also be rehabilitated

and in this connection all pipes and valves will be renewed.

Water supply guaranteed

The engineer responsible for the supervision

of works, Richard Raith from IRPS GbR, Stuttgart, explaines the

material requests put out to tender: "We attach importance

to a high-quality thick coating with a relatively low porosity".

In the meantime, the rehabilitated chamber is in operation again

and both the second chamber and the mixing tank can presently be

rehabilitated in parallel. In July 2012, all jobs should be finished

and then the completely renewed tank will be in normal operation

again.

epasit: Solutions for building materials

from a single source.

For more than 50 years, the epasit GmbH develops

and produces special building materials for rehabilitation, renovation

and modernization. The product range comprises, among other things,

the waterproofing of buildings, the rehabilitation of monuments

and old buildings as well as the rehabilitation of damages caused

by mould and moisture. Drinking water tanks or swimming pools, too,

are rehabilitated with products from epasit. With sought after inventions

for building protection and building rehabilitation, the family

company distinguishes itself as a think tank. In addition to thousandfold

proved standard products, epasit develops individual solution for

its customers.

Press

contact:

epasit GmbH Spezialbaustoffe

Peggy Wandel

Sandweg 12 - 14, D-72119 Ammerbuch-Altingen,

Tel (+49) 0 7032 2015-0, Fax (+49) 0 7032 2015-21

E-mail: presse@epasit.de

|

|

FURTHER OBJECTS:

Gymnasium zu Bratislava

Burg zu Bratislava

Trinkwasserbehälter

Lindau

Altes Rathaus

Bonn

Stadtgymnasium

Helsinki

Jugendstilvilla

in Aalen

Jugendstilvilla

in Aalen

Waldseer

Hof Markdorf

Waldseer

Hof Markdorf

Therme

Rügen

Therme

Rügen

Schimmelalarm im

Badezimmer

Diakonie-Gebäude

Witten

Leonhardskirche English

>>

Deutscher Kaiser

English

>>

Wilhelma Stuttgart English

>>

Trinkwasserbehälter English

>>

Hafenviertel Tallinn English

>>

EZB Frankfurt English

>>

Zwinger Dresden English

>>

Contact

us

Do you have questions and need

a personal contact?

Phone +49 (0)7032

- 20 15-0

Project management

Ralph Weber

If you have further questions regarding this object or a similar

problem, please contact us.

Contakt us

e-Mail:

ralph.weber@epasit.eu

Phone:

+ 49(0)7345 - 22 333

+ 49(0)172 - 745

29 14

|